Tooling department

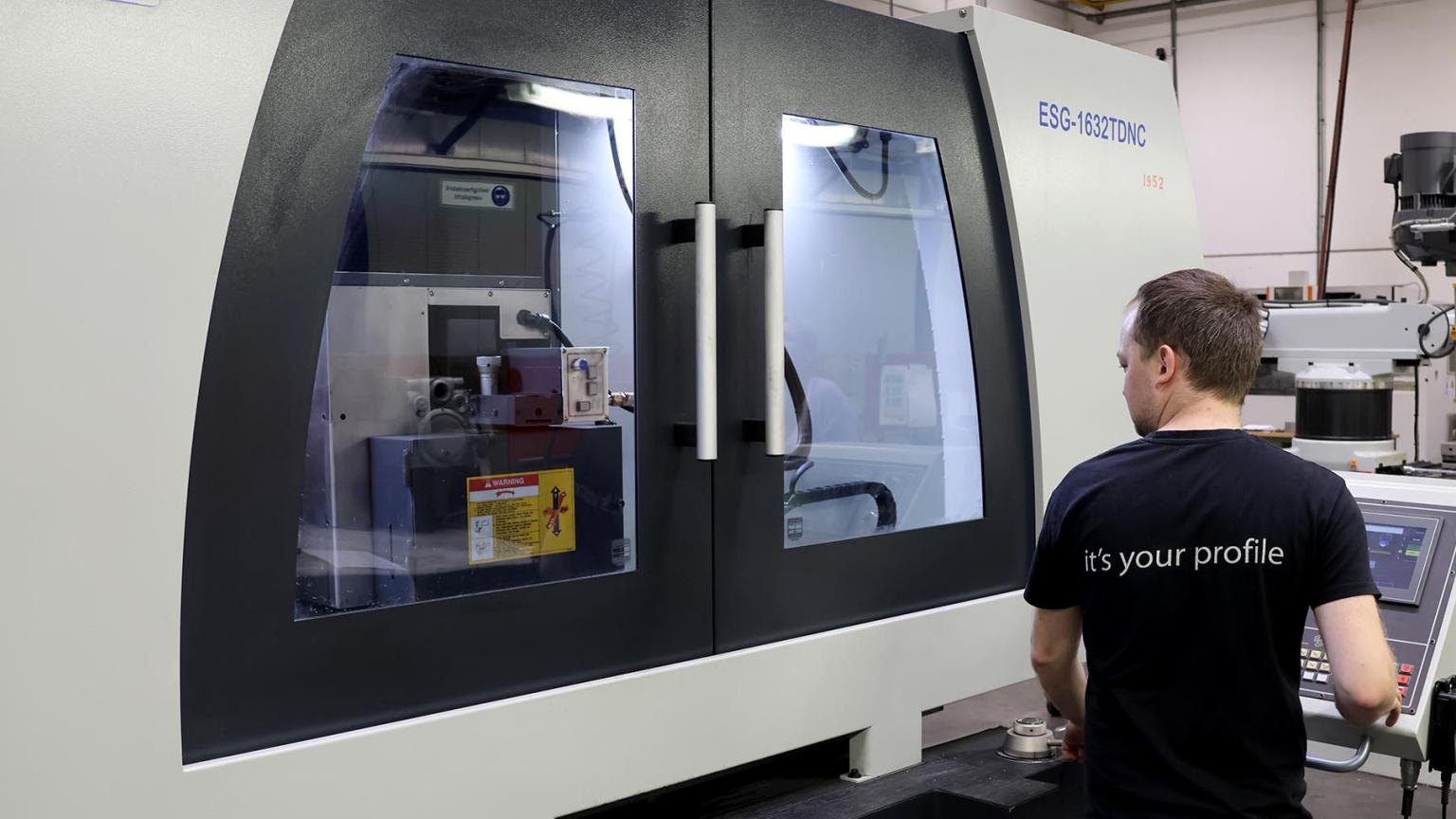

We have our own tooling department. Thanks to our expertise, we are able to produce, maintain and optimize the tools In house.

We have in-depth insight into every step in the process, which means we can make any adjustments and improvements during production.

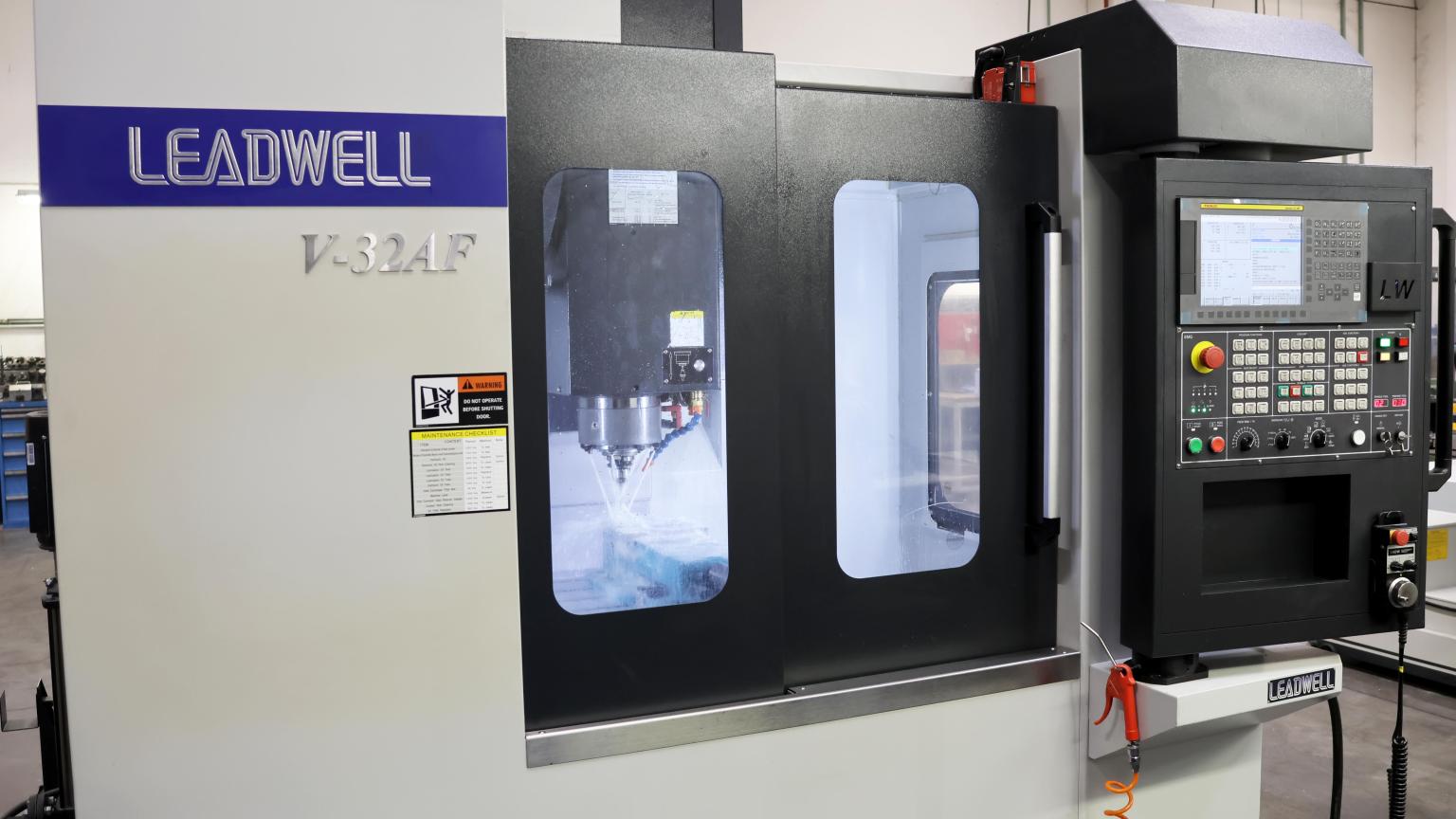

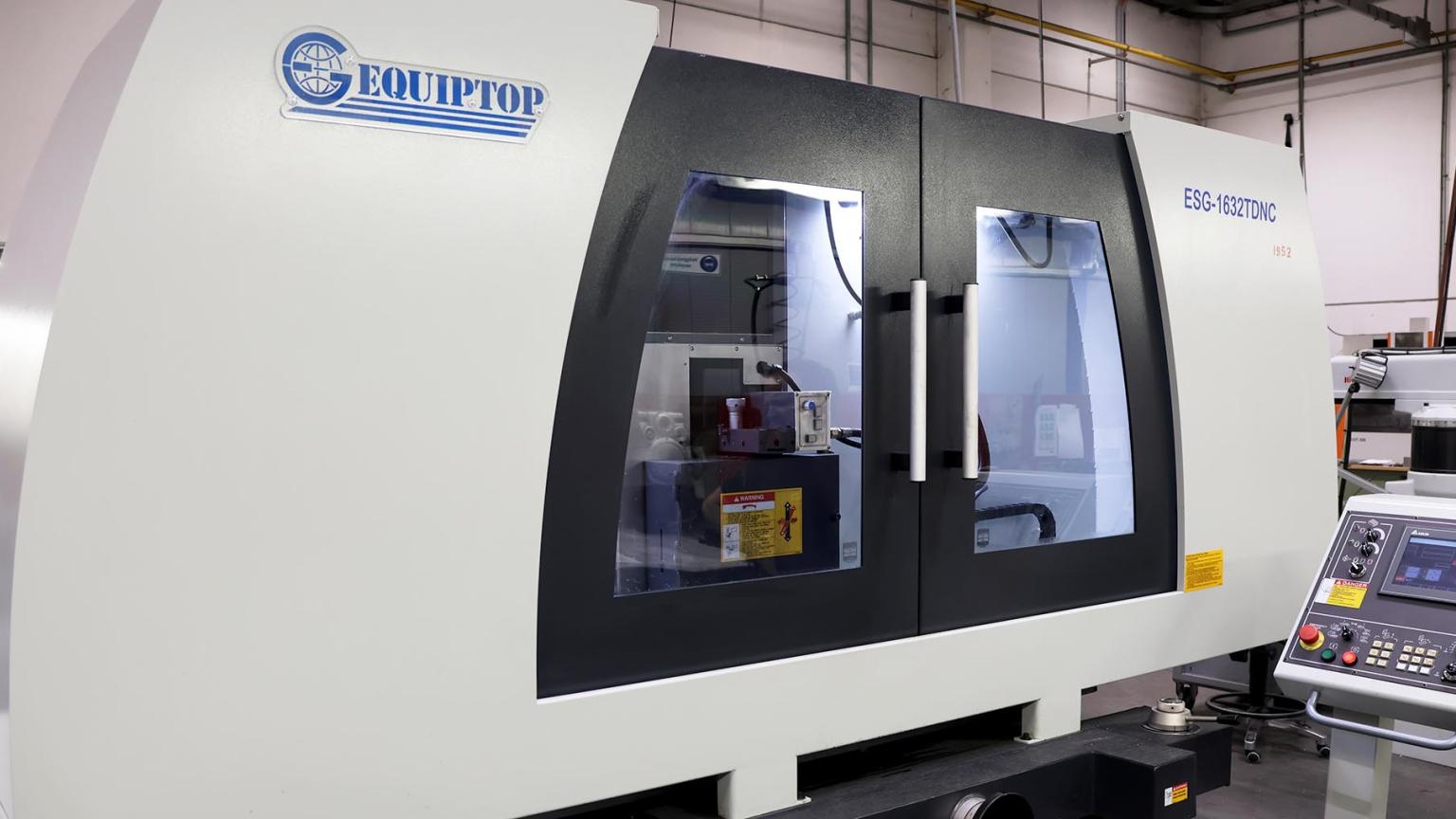

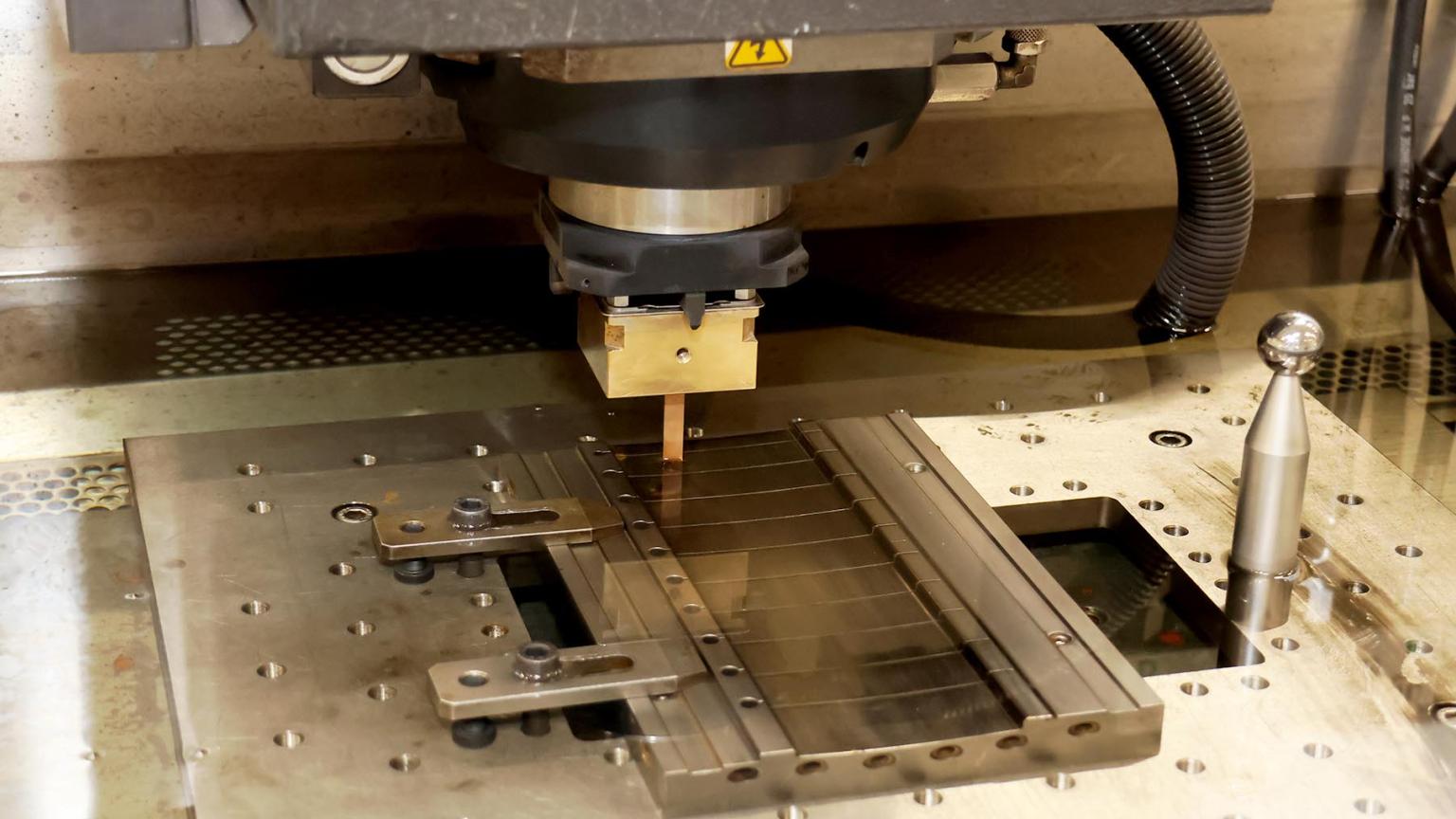

We have an advanced machinery park with CNC machining centres, a surface grinding machine, wire cutting EDM machines, a die sinking EDM machine, a EDM hole drilling machine, a vertical milling machine, a conventional lathe machine, pillar drilling machines, a conventional milling machine and a thread tapping machine.

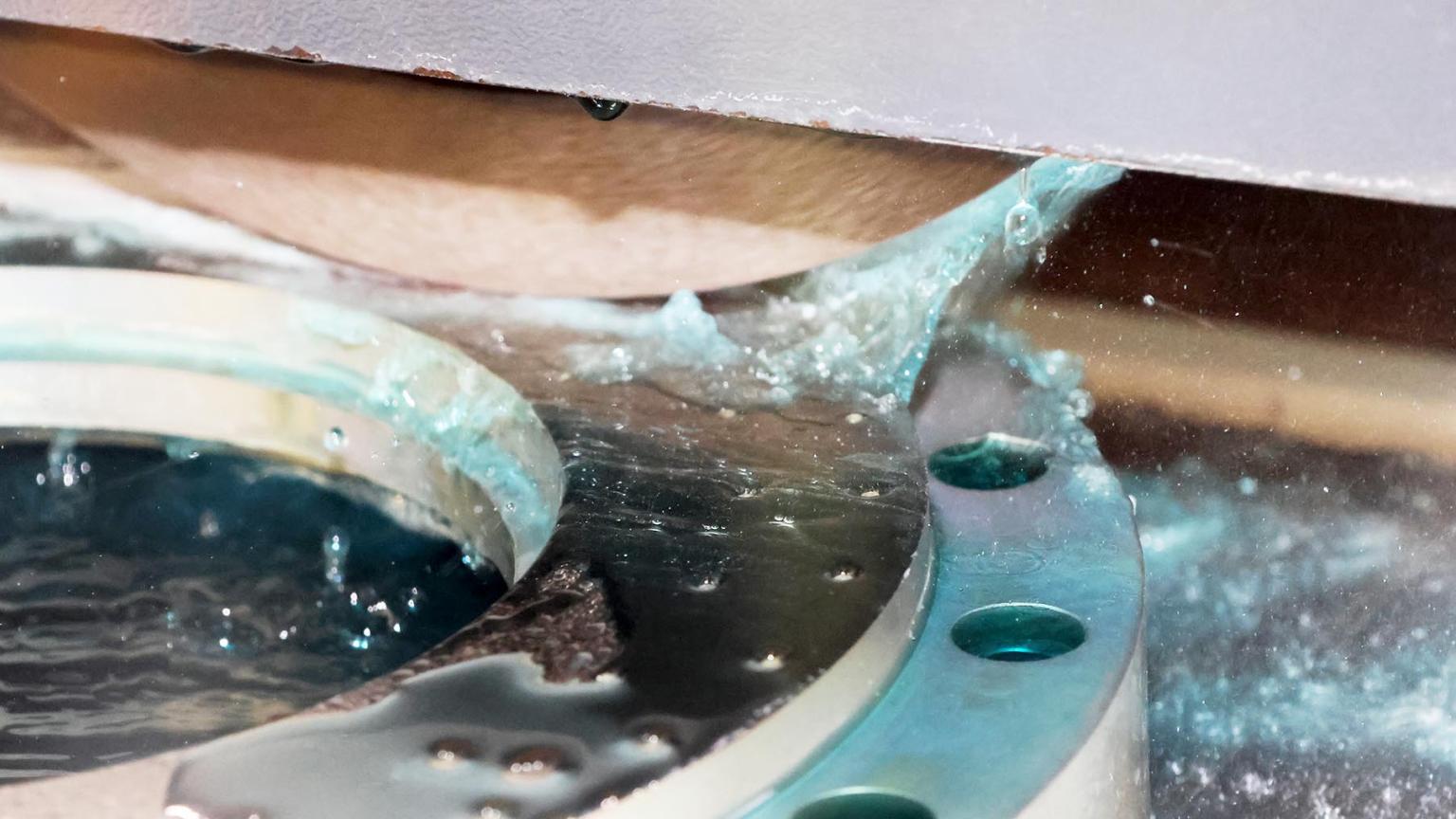

Our CNC precision machines enable us to manufacture the shape and caliber of our tools with great accuracy. When the tool is ready, it undergoes a trial extrusion under the guidance of an engineer from our R&D team. This way we can immediately assess and implement any corrections in our mold making facility. This process results in a fully production-ready mould.